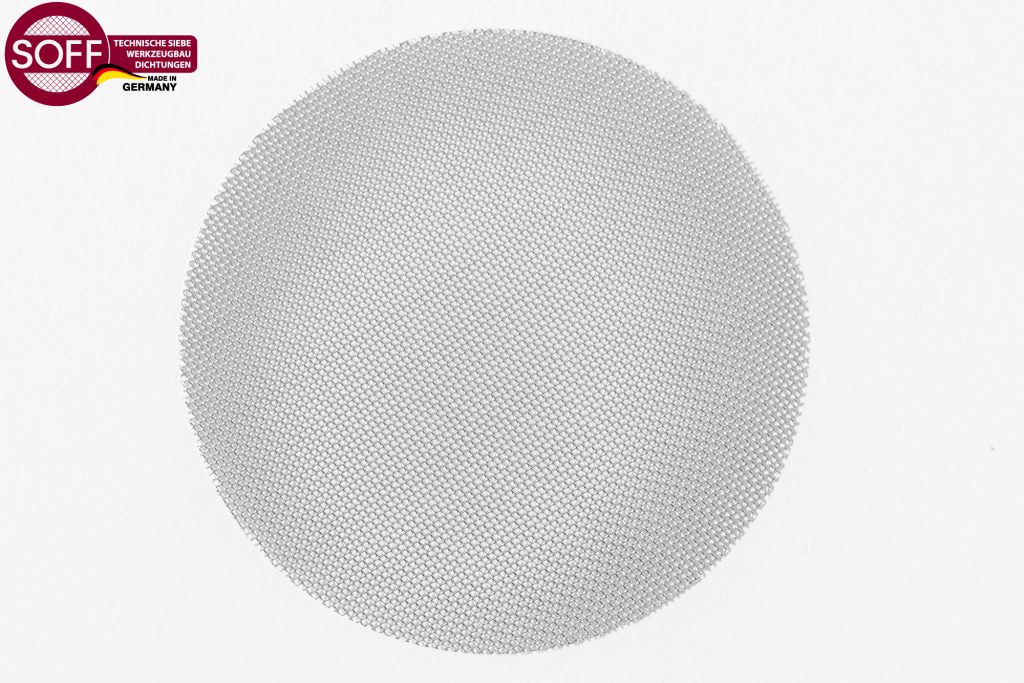

Discs made of wire mesh

Rondelles from Wire Mesh

Simple Rondelles from Wire Mesh / Filter Rondelles

We manufacture simple rondelles from wire mesh and filter rondelles as stamped parts starting from a diameter of 3 mm. For our punching machines, we have several hundred different punching tools, so almost every diameter is already available. We manufacture special punching tools in our in-house tool shop.

Strip Punching Machine for Large Quantities

To economically produce larger quantities, a strip punching machine is essential. Our machine park includes a self-designed and manufactured strip punching machine, which is used for punching larger quantities. The machine was specially adapted to our machines and can be quickly and easily mounted on all punching machines.

Punching or Laser Cutting

Depending on the available tool, production is carried out as a stamped part or as a laser cut. Laser cutting allows the production of more complex geometries such as oval, polygonal, or kidney-shaped without tools, eliminating high initial or tool costs. Wire mesh with strong wire is better suited for laser cutting than punching. However, some very fine rondelles from wire mesh can only be punched.

Edge Breakage and Mesh Distortion

Stamped rondelles are often used as simple loose inserts. Mesh distortion and broken wires at the cut edges are unavoidable when processing normal wire mesh. For some production processes, mesh distortion and broken wires pose a significant problem, as loose wires can disrupt the process and shifted meshes can affect the filter fineness. Processing diffusion-annealed and calendered wire mesh eliminates these problems. DKS wire mesh has the following properties:

-

No mesh distortion

-

No wire breakage at the cut edges

-

Free from particles

DKS Wire Mesh

DKS wire mesh is specially developed mesh that has been optimized through diffusion annealing and calendering. These processes ensure that the mesh has no mesh distortions or wire breakages at the cut edges and is free from particles. These properties make DKS wire mesh particularly suitable for applications requiring the highest precision and cleanliness.

DKS Mesh as Optimal Material for Punching Machines

DKS wire mesh is the optimal material for use in punching machines. Due to its special properties, such as no mesh distortion and no wire breakage at the cut edges, it ensures high process reliability and quality in the production of stamped parts. The diffusion-annealed and calendered mesh is particularly robust and resistant, making it ideal for use in automated punching processes.

Wire Mesh and Quality

We manufacture rondelles from wire mesh made of stainless steel (1.4301, 1.4401), copper, brass, metal fiber fleece, polyester fleece, and many other materials. All wire mesh rondelles are delivered oil- and grease-free as standard. Upon request, the wire mesh rondelles can be cleaned again by ultrasound with special cleaning solutions. Additionally, the filter rondelles can be straightened upon request, which is particularly important for the flatness of very fine mesh types.