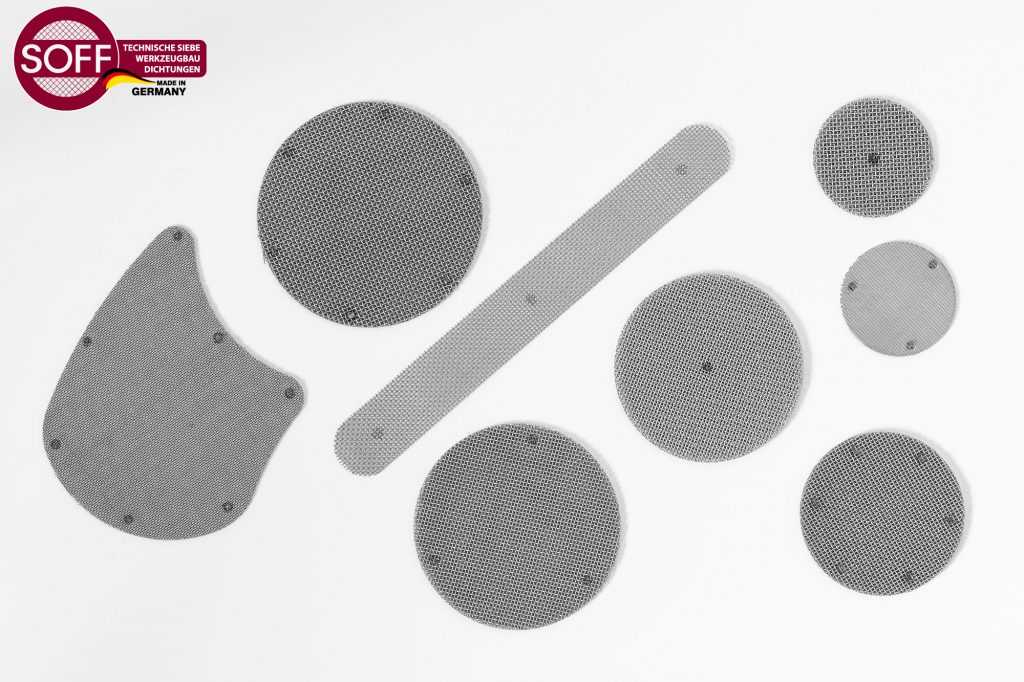

Strainer screens Extruder screens

Strainer screens are typically used in plastic, silicone rubber, or rubber/gum extrusion systems or strainer systems. These screens are crucial for the filtration and purification of materials during the extrusion process to ensure high product quality.

Strainer screens usually consist of multi-layer wire mesh discs with different filter fineness. These multi-layer structures allow foreign substances and impurities to be effectively retained depending on the mesh size or filter fineness. The various layers of the wire mesh provide graduated filtration, removing both coarse and fine particles.

Wire mesh made of steel or stainless steel are the most commonly used meshes for this application. Steel mesh offers high strength and durability, while stainless steel mesh is additionally corrosion-resistant, ensuring a longer lifespan in demanding environments.

An important aspect in the production of strainer screens is spot welding. This technique is used to securely connect the different layers of the wire mesh. Spot welding creates a stable and durable connection, ensuring that the screens maintain their shape and function even under high loads and in demanding environments. Spot welding allows for precise and uniform connections, ensuring the integrity of the screen.

In addition to conventional spot welding, micro spot welding is also used. This technique allows for very small and precise weld points, which are particularly suitable for fine and delicate wire mesh. Micro spot welding offers the advantage of minimally affecting the structure of the wire mesh while still creating a strong and durable connection. This method is ideal for applications where the highest precision and minimal material alteration are required.

For pre-series production or for testing purposes, we also manufacture smaller quantities in different designs for you. This flexibility allows prototypes to be tested and adjustments to be made before production begins on a larger scale. Our customized solutions ensure that your specific requirements are met and that you achieve the best possible performance of your extrusion systems.

Extruder screens made of wire mesh round, oval, and kidney-shaped